ExtendSim popularity in higher institutions has experienced phenomenal growth as researchers have learned of ExtendSim's ease of use combined with its high level of accuracy. ExtendSim has become an indispensable component supporting essential phases of innovative research projects in universities worldwide.

ExtendSim popularity in higher institutions has experienced phenomenal growth as researchers have learned of ExtendSim's ease of use combined with its high level of accuracy. ExtendSim has become an indispensable component supporting essential phases of innovative research projects in universities worldwide.

In response to the growing popularity of using ExtendSim in research projects, we established the ExtendSim Academic Research Grant program. Under the Grant, the ExtendSim Team supports students who are obtaining an advanced degree (Masters Thesis, PhD, or PostDoc) by subsidizing the cost of a full Model Developer Edition of ExtendSim for use by the student during the term of their research project. In exchange, the student provides a description of the research and quarterly updates throughout the term of the project. At the end of the research, all findings (ie. paper, project, etc.) and the ExtendSim model formulated are passed on to ANDRITZ Inc. for publication on the ExtendSim web site.

apply for an Academic Research Grant ![]()

see completed Academic Research Grants ![]()

update form for current Academic Research Grant holders ![]()

Current Academic Research Grants

These research projects have been awarded an ExtendSim Academic Research Grant and are currently in progress. To learn about past projects completed under the ExtendSim Academic Research Grant program, please see Academic Research Grants Fulfilled.

![]() Healthcare • Optimization of Medical Physics Services in a Radiotherapy Center

Healthcare • Optimization of Medical Physics Services in a Radiotherapy Center

Simulation and Optimization of Medical Physics Services in a Radiotherapy Center

Simulation and Optimization of Medical Physics Services in a Radiotherapy Center

Maria Belen Santos

Bachelor's Degree in Biomedical Engineering

National University of Córdoba - Cordoba, Argentina

Grant awarded: July 2, 2025

To be completed: January 1, 2026

Hypothesis.

A discrete event simulation model that includes both core and auxiliary tasks of medical physicists and dosimetrists can reveal critical inefficiencies in resource usage and improve the planning and organization of medical physics services.

Project description.

This project aims to simulate the internal workflow of the medical physics service in a radiotherapy center in Córdoba, Argentina. The focus is on the daily operations of medical physicists and dosimetrists, not only in treatment planning and dosimetry tasks, but also including residency training, audits, administrative duties, quality assurance, and other non-clinical activities that affect service availability and performance.

The model will represent real-life constraints in human resource allocation and technical equipment usage. By simulating typical and high-demand days, we will identify workflow bottlenecks, measure the impact of parallel tasks, and evaluate scenarios to optimize efficiency without compromising quality or safety.

Questions this research will answer.

- How do additional responsibilities (e.g. audits, training, admin work) affect the availability of physicists and dosimetrists for patient-related tasks?

- What is the resource utilization rate, and where are the key inefficiencies?

- Which organizational strategies can improve the balance between mandatory duties and clinical work?

- How can the center better respond to increased patient load while maintaining service quality?

How research strategy will be designed to help answer these questions.

We will gather detailed data on task types, durations, resource availability, and overlapping responsibilities from a real radiotherapy center. Using ExtendSim DE, a modular and hierarchical model will be developed to reflect the complexity of these interrelated processes.

By simulating different workday structures and scenarios (e.g. increased audit days, changes in resident activity), we will evaluate performance metrics such as task delays, idle time, and staff overutilization. We will use this to propose informed workflow adjustments.

How ExtendSim will be used in this project.

ExtendSim DE will allow us to simulate the concurrent execution of clinical and non-clinical tasks using discrete-event logic, resource management, and queues. The visual and modular environment of ExtendSim is ideal for integrating multiple roles, priorities, and task flows in a realistic healthcare setting.

What is unique about this project?

Most research on radiotherapy focuses on treatment optimization and patient outcomes. This project, however, shifts the focus to the internal structure of the medical physics service — an often overlooked but essential component of safe and effective treatment. Including non-clinical but mandatory tasks such as audits and training in the simulation makes the model much more realistic and useful for operational planning.

Why the interest in the indicated subject?

As a biomedical engineering student, I’m passionate about improving healthcare delivery by optimizing internal hospital processes. I chose this topic because I believe medical physicists and dosimetrists are key professionals whose work often goes unseen in planning models. Making their full workload visible and manageable through simulation is a way to contribute to a more efficient and fair system.

What impact will this research make to the existing current state of knowledge?

The simulation model will provide a structured way to visualize and evaluate how medical physicists and dosimetrists manage both clinical and non-clinical duties. It will offer a tool for administrators to test new staffing or scheduling policies before implementing changes. This approach could be replicated in other services or institutions, promoting better planning across the healthcare sector.

Publications.

Coming Soon!

Updates.

Coming soon!

![]() Healthcare • Optimization of System Operations

Healthcare • Optimization of System Operations

Maram Battisha

Bachelor's Degree

Arab Academy For Science, Technology And Maritime Transport, Industrial & Management Engineering - Alexandria, Egypt

Grant awarded: January 6, 2025

To be completed: October 1, 2025

Hypothesis.

The hypothesis for this project is that integrating a dynamic, data-driven simulation model can optimize healthcare system operations by improving resource allocation, reducing patient wait times, and enhancing overall patient satisfaction. Specifically, using tools like ExtendSim to simulate healthcare processes will highlight inefficiencies and offer strategies for improvement in real-world healthcare settings.

Project description.

The research plan involves creating a comprehensive model of a healthcare system, incorporating elements like patient flow, staffing, resource allocation (such as beds, medical equipment, and medications), and wait times. This model will be constructed using ExtendSim, a simulation software that allows for visualizing and analyzing complex systems. The goal is to identify bottlenecks in healthcare operations and propose strategies to enhance efficiency without compromising patient care. The project will involve data collection from existing healthcare systems, setting up the simulation model, and running various scenarios to assess potential improvements.

Questions this research will answer.

- What are the primary factors contributing to inefficiencies in healthcare systems, particularly in terms of patient wait times and resource allocation?

- How can a simulation model optimize resource allocation to reduce wait times and improve patient care?

How research strategy will be designed to help answer these questions.

- Literature Review: To understand current inefficiencies and identify relevant factors affecting healthcare systems.

- Data Collection: Obtain data on patient flow, wait times, resource usage, and staffing from healthcare facilities

- Model Building: Develop a dynamic simulation model using ExtendSim to replicate the healthcare system.

- Scenario Testing: Run multiple scenarios with varying parameters (e.g., staffing levels, patient arrivals, and resource availability) to identify improvements.

- Analysis: Analyze the simulation results to uncover inefficiencies and suggest actionable solutions for improving healthcare operations.

- Optimization: Refine the model based on findings and explore optimization strategies to enhance patient care and system performance.

How ExtendSim will be used in this project.

ExtendSim will be used to create a simulation model of the healthcare system that integrates various components, such as patient flow, resource allocation, and staffing. The tool will simulate different operational scenarios and allow for testing various interventions (e.g., changes in staffing, resource levels) to assess their impact on system performance. By adjusting the parameters within ExtendSim, the research will uncover solutions to improve efficiency and patient satisfaction while minimizing wait times and maximizing resource utilization.

What is unique about this project?

This project is unique because it applies simulation modeling to a comprehensive healthcare system, taking into account multiple dynamic factors such as patient arrival rates, resource availability, and staffing. Unlike simpler models that focus on one aspect of healthcare, this project aims to simulate the entire system's operations. Furthermore, by using ExtendSim, a robust simulation tool, the project provides a more accurate and actionable framework for real-world healthcare system improvements.

Why the interest in the indicated subject?

The healthcare sector faces numerous challenges, including long patient wait times, overburdened resources, and inefficiencies in care delivery. These challenges directly affect patient satisfaction and the overall quality of care. I am interested in this project because improving healthcare delivery using data-driven methods and simulations can lead to meaningful changes that improve public health and reduce inefficiencies. Additionally, healthcare systems are complex and multifaceted, which presents a rewarding challenge for creating impactful solutions.

What impact will this research make to the existing current state of knowledge?

This research will contribute to the healthcare field by providing actionable insights for improving system efficiency. By applying simulation modeling, healthcare administrators will gain a clearer understanding of how various operational changes affect patient outcomes and resource utilization. Ultimately, this project could inform decision-making processes in healthcare systems, leading to improved care delivery, reduced costs, and better patient satisfaction.

Publications.

As this is an initial research proposal, no publications related to this specific topic have been authored yet. However, I am confident that the results of this project will lead to valuable findings and potential publications in healthcare management or simulation modeling journals.

Updates.

Coming soon!

Industrial Symbiosis Network • Agri-Food Sector

Modelling and Evaluating an Industrial Symbiosis Network in Agri-Food Sector through advanced simulation - Moving towards circular economy in the UK

Modelling and Evaluating an Industrial Symbiosis Network in Agri-Food Sector through advanced simulation - Moving towards circular economy in the UK

Vikram Ramakrishnan

PhD in Management

Queen's University Belfast, United Kingdom

Grant awarded: May 25, 2024

Original completion date: September 30, 2025

Extended to: December 31. 2025

Hypothesis.

The hypothesis of this research proposes that developing an Industrial Symbiosis Network centered around a cheese factory, with symbiotic partnerships involving a beer brewery, soap producer, anaerobic digester, dairy farm, and sports nutrition factory, can significantly contribute to sustainable production practices and circular economy principles. Leveraging Material Flow Analysis, the study aims to develop and quantify resource flows within the network and evaluate its technical feasibility, economic viability, and environmental implications. Additionally, by constructing a process-based simulation model of the cheese factory, the research seeks to assess the network's performance in terms of technical feasibility, economic viability and environmental implications against operational disruptions. It is hypothesised that the establishment of such an integrated network will enhance resource efficiency, minimize waste generation, and foster mutually beneficial relationships among the symbiotic partners, ultimately promoting sustainable industrial practices and circular economy initiatives.

Project description.

The research follows a 3-paper format for each year (currently in Year 3):

- Year 1: Paper 1 - Literature Review on Industrial Symbiosis modelling approaches and IS indicators.

- Year 2: Paper 2 - Analysing Industrial Symbiosis Opportunity through Material Flow Cost Accounting: A Perspective of Dairy Production & Processing Unit in Northern Ireland.

- Year 3: Paper 3 - An Investigation into the Operational Vulnerabilities in Industrial Symbiosis Network Involving Dairy Processors and Producers.

Questions this research will answer.

- Research Question 1 (Paper 1): What are the suitable modelling approaches for designing an Industrial Symbiosis Network anchored around dairy production and processing?

- Research Question 2 (Paper 2): What are the technical feasibility, economic viability and environmental implications of an Industrial Symbiosis Network developed around Dairy Processors and Producers?

- Research Question 3 (Paper 3): What are the operational vulnerabilities in Dairy Processing & Production and what will be their implications on the technical, economic and environmental performance of the Industrial Symbiosis Network with dairy processors as anchors?

How research strategy will be designed to help answer these questions.

To model and evaluate Industrial Symbiosis in Agri-Food Networks, particularly taking the case of dairy production and processing, this research has been broadly divided into three phases.

- Phase I (Year 1)

- To find a suitable method which can model such an IS network to capture key resource flows and the dynamic nature of those flows, further indicators that can evaluate the synergic performance.

- Methodology: Literature Review on IS modelling approaches and IS indicators.

- Result: Material Flow Analysis to develop the Industrial Symbiosis Network and Discrete Event Simulation to incorporate dynamic properties to analyse its performance under vulnerabilities.

- Phase II (Year 2)

- To capture the key resource flows (quantification), which will be key synergy flows in the proposed IS network model and key stages in the production which can have an impact on the quantification of by-products.

- Methodology: Material Flow Modelling using STAN2.7 software; Literature and Empirical data collection to validate.

- Result: Performance of Industrial Symbiosis Network in terms of technical feasibility, economic viability and environmental implications.

- Phase III (Year 3)

- A Process-based Simulation Model to evaluate the performance of a developed IS network.

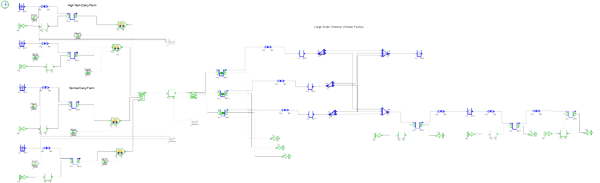

- Methodology: Simulation Model of a Cheese Factory in ExtendSim Pro software using Discrete Events and Discrete Rate Library; Empirical Data used to Validate.

- Expected Result: Performance of Industrial Symbiosis in terms of technical feasibility, economic viability and environmental implications under operational disruption in Cheese Factory affecting cheese whey flow.

How ExtendSim will be used in this project.

ExtendSim will be used in phase 3 i.e. year 3 of this research project to develop an advanced process-based simulation model of a cheddar cheese factory using the discrete rate and discrete event module in the ExtendSim Pro. The model will be simulated with scenarios developed where the impact on quality & quantity of cheese whey (by-product) due to disruptions and the factors which affect them will be analysed. The performance of the developed Industrial Symbiosis Network will be analysed under each scenario in terms of technical feasibility, economic viability and environmental performance.

What is unique about this project?

This research stands out due to its focus on the operational vulnerabilities within symbiotic industrial networks, particularly in sectors characterised by dynamic resources like milk and its derivatives. Unlike existing literature, this study aims to fill the gap by employing discrete event simulation techniques to comprehensively analyse the network's functioning in a process-based manner. By combining principles of circular economy, waste management and advanced simulation technique, this research offers a novel approach to understanding and mitigating risks within Industrial Symbiosis Networks. This unique perspective facilitates a deeper exploration of resource optimisation, waste minimisation, and environmental enhancement, contributing significantly to the advancement of circular economy practices.

Why the interest in the indicated subject?

This topic holds immense importance due to the escalating challenges posed by population growth, resource scarcity, and environmental degradation. The agri-food sector, a major contributor to these issues, impacts the environment through deforestation, water depletion, greenhouse gas emissions etc. Implementing sustainability and circular economy practices is crucial to mitigate these impacts. Investigating and embracing these principles can potentially unlock efficient resource utilisation, reduce environmental footprint, and foster resilience in the face of adversity.

What impact will this research make to the existing current state of knowledge?

The findings can help the dairy industry and the symbiont partners to understand and integrate sustainable supply chain practices and waste management techniques, and further unlock potential benefits of symbiotic relationships among themselves. Also, the insights gained through this research can be further used for developing Industrial Symbiosis models for more complex scenarios.

Publications.

Not yet. Working on the call for papers in a couple of ABS 3 Journals.

Updates.

October 1, 2025 - In the last two quarters, the core elements of the model and the structure were kept the same, but more experimental scenarios were developed by changing parameters in the model. The model of the dairy farm to cheese factory is full, with the PhD project coming close to completion.

January 2, 2025 - The model has been updated and improved in two main aspects:

January 2, 2025 - The model has been updated and improved in two main aspects:

- Enhance and update the dairy farm and cheese factory operations and processes to make them more realistic.

- To improve randomness using more suitable distribution in multiple blocks involved in the model.

Progress on ExtendSim model: The model has been revised and updated through more interviews and factory visits conducted in the last 4 months. Dairy Farms have been further categorised into High-Tech Dairy Farms (Sophisticated equipment involved in production) and Normal Dairy Farms (Less sophisticated equipment). In the Cheese Factory part of the model, more processes involving whey processing have been developed and updated in the model with parameters collected from a local large-scale cheese factory in Northern Ireland.

July 10, 2024 - Modeling Dairy Production from a Dairy Farm and Dairy Processing center to a Cheese Factory was worked on in this quarter. Discrete Rate and Discrete Event libraries were used to build the model using Valve, Tank, Diverge, Create, Queue, Exit, and Interchange blocks. The model has been developed but the parameters considered in the model needs to work on to develop realistic scenarios to study the model under different types of disruptions. The base of the simulation model has been built, now the coming weeks the model will be worked on to enhance it with realistic parameters in terms of flows/travel times or other operations and what distributions to use under each scenarios developed. The grantee has planned to speak to individuals from the dairy industry (particularly cheese producers) in the coming weeks/months to enhance this simulation model of dairy farm and cheese factory particularly in the parameters to include randomness into the model and enhance the study to more realistic scenarios.

July 10, 2024 - Modeling Dairy Production from a Dairy Farm and Dairy Processing center to a Cheese Factory was worked on in this quarter. Discrete Rate and Discrete Event libraries were used to build the model using Valve, Tank, Diverge, Create, Queue, Exit, and Interchange blocks. The model has been developed but the parameters considered in the model needs to work on to develop realistic scenarios to study the model under different types of disruptions. The base of the simulation model has been built, now the coming weeks the model will be worked on to enhance it with realistic parameters in terms of flows/travel times or other operations and what distributions to use under each scenarios developed. The grantee has planned to speak to individuals from the dairy industry (particularly cheese producers) in the coming weeks/months to enhance this simulation model of dairy farm and cheese factory particularly in the parameters to include randomness into the model and enhance the study to more realistic scenarios.

![]() Lean Manufacturing • Impact of Preventative Maintenance

Lean Manufacturing • Impact of Preventative Maintenance

Examining the Impact of Preventative Maintenance in a Lean Manufacturing Environment using Simulation Models

Examining the Impact of Preventative Maintenance in a Lean Manufacturing Environment using Simulation Models

Mohammed Al Ghaithi

Bachelor's Degree in Mechanical & Manufacturing Engineering

Dublin City University - Dublin, Ireland

Grant awarded: January 31, 2025

To be completed: July 1, 2025

Hypothesis.

Setting up different variations in maintenance plans influences the production cycle time especially with highly utilized machines.

Project description.

Making an example simulation model and applying preventative maintenance to it to experiment with variations in production cycle time.

Questions this research will answer.

Studying the impact of scheduled and unscheduled maintenance plans and their different variations on an example production system by measuring different KPIs.

How research strategy will be designed to help answer these questions.

Simulating an example manufacturing system and applying lean manufacturing techniques and shutdowns to apply maintenance and failure of machines.

How ExtendSim will be used in this project.

Used as a simulation tool of the system and machine failures and maintenance plans.

What is unique about this project?

This project proves the basics of applying maintenance plans as close as it can be to a real world application.

Why the interest in the indicated subject?

As part of my course, it is to my interest to learn more about organisation of manufacturing systems and their care maintenance plans which keep them efficient.

What impact will this research make to the existing current state of knowledge?

The results obtained from the study will go towards general education purposes for upcoming generations of manufacturing engineering students.

Publications.

Coming soon!

Updates.

Coming soon!

![]() Oil Processing Plant • Integrating Smart Heat Exchanger Systems

Oil Processing Plant • Integrating Smart Heat Exchanger Systems

Smart Heat Exchanger for Oil Plants

Smart Heat Exchanger for Oil Plants

Jana Amr, Ahmed Abdellatif, Moataz Khaled, Omar El Sayed, and Yassin Awny

Bachelor's Degree in Industrial & Management Engineering

Arab Academy For Science, Technology And Maritime Transport, Industrial & Management Engineering - Alexandria, Egypt

Grant awarded: May 16, 2025

To be completed: February 1, 2026

Hypothesis.

The integration of smart heat exchanger systems into oil processing plants can significantly improve cooling efficiency, reduce idle time, and enhance overall production performance compared to traditional natural cooling methods.

Project description.

- Analyze the current cooling process in the oil plant and identify inefficiencies.

- Design a customized smart heat exchanger system incorporating sensors, pumps, and nanofluids.

- Evaluate the impact of reduced cooling time on productivity through simulation and prototyping.

- Implement and test a physical prototype to validate performance improvements

- Assess the economic feasibility through benefit-cost analysis and calculate the payback period.

- Assess the economic feasibility through benefit-cost analysis and calculate the payback period.

Questions this research will answer.

- What inefficiencies exist in the current oil cooling system?

- How can smart technologies enhance the performance of heat exchangers?

- What are the economic and environmental impacts of implementing a smart heat exchanger system?

- How does the use of nanofluids and sensor integration affect cooling efficiency?

How research strategy will be designed to help answer these questions.

- Conduct a literature review to identify current challenges and technologies.

- Use Fishbone and gap analysis to understand root causes and bridge performance gaps.

- Perform system design including geometry and fluid modifications.

- Use AHP analysis to select optimal system components.

- Conduct economic impact analysis to measure ROI, savings, and payback period.

- Develop a prototype and test it to measure improvements in cooling time and production output.

How ExtendSim will be used in this project.

ExtendSim will be used to:

- Simulate the existing and proposed cooling processes.

- Model system dynamics including flow, temperature changes, and idle time reduction.

- Evaluate various heat exchanger configurations and operational parameters.

- Visualize and quantify the performance improvements before physical implementation.

What is unique about this project?

- Combines smart sensor integration and nanofluid-based thermal management.

- Applies industrial engineering principles to modernize traditional oil plant operations.

- Designs a customized double-pipe heat exchanger with advanced geometry for improved heat transfer.

- Includes a prototype and cost-benefit analysis to bridge theoretical design and real-world application.

Why the interest in the indicated subject?

The subject combines multiple engineering domains—mechanical, industrial, and energy—with a clear real-world application. It aligns with the global push for smarter, energy-efficient systems in traditional industries and offers an opportunity to make a measurable impact on industrial sustainability and performance.

What impact will this research make to the existing current state of knowledge?

- Sets a precedent for modernizing thermal management systems in oil and other process industries.

- Demonstrates how smart technologies can replace outdated cooling methods.

- Encourages adoption of IoT-based monitoring and nanotechnology in industrial applications.

- Provides a scalable model for other facilities facing similar challenges.

Publications.

None yet.

Updates.

Coming soon!

Operational Flow • Nuclear Waste Management

Alexis Andaverde

PhD in Industrial Engineering

Florida State University, College of Engineering - Tallahassee, FL USA

Grant awarded: October 31, 2024

To be completed: July 1, 2028

Hypothesis.

We hypothesize that making structural changes to a typical nuclear waste disposal process can enhance waste handling throughput and process time. We can leverage ExtendSim to develop a discrete event model, or digital twin, of a nuclear waste disposal process. This discrete event simulation will provide valuable insights into the processes bottlenecks and required resource allocation to achieve steady and favorable system dynamics.

Project description.

The research will focus on modeling the operational flow of a general nuclear waste management through discrete event simulation. This approach will offer a more comprehensive understanding of waste disposal processing improvements that ensure long-term safety, regulatory compliance, and nuclear accountability in nuclear waste management.

The study will begin with the development of a baseline model that represents typical waste disposal operations. This baseline model includes processes from the moment waste arrives at the site, waste inspection, transportation of waste to underground facilities, waste emplacement, and truck departure. The baseline model will be a composition of three sequential processes.

Once the baseline model is created, a detailed analysis will be conducted to identify inefficiencies and bottlenecks at various stages. Stress tests and sensitivity analyses will follow to assess system performance under varying conditions, such as increased waste loads, equipment failures, and varying safety risks.

The final phase of the research will involve making structural changes to baseline model. The structural changes will be informed by the inefficiencies identified and consultations with practitioners in the field. Overall, this work will help us gain insights into safer, more cost-effective, and efficient nuclear waste dispositioning processes.

Questions this research will answer.

- What are the major bottlenecks in nuclear waste disposal operations from waste arrival to final truck departure?

- How does resource allocation (e.g., trucks, staff, equipment) impact the efficiency and cost of operations?

- What are the key performance indicators that affect the system's performance, and how sensitive is the system to changes in these variables?

- How can different operational scenarios, such as increased waste volumes or changes in schedules, be optimized for better overall system performance?

- How can a typical nuclear waste disposal process be made more resilient to disruptions, ensuring regulatory compliance and safety?

- What structural enhancements can be made to the nuclear waste disposal process?

How research strategy will be designed to help answer these questions.

- Modeling Current System: Using ExtendSim, we will create a detailed discrete event simulation of a nuclear waste disposal system, representing the flow from waste arrival to underground placement to final truck departure.

- Data Collection: Use existing public operational data on current processes, including waste transportation, storage, and handling times. Use expert opinion to provide estimates of any remaining required inputs.

- Managerial Insight Analysis: Identify bottlenecks, inefficiencies, and strengths in the current system, using data from the model.

- Stress Testing & Sensitivity Analysis: Perform stress tests and sensitivity analysis to evaluate how the system responds to changes in key parameters, such as increased waste loads, equipment breakdowns, or scheduling changes.

- Propose and Evaluate System Improvements: Develop additional discrete event simulation models that mimic different operational scenarios evaluate scenario performance of KPIs compared to the baseline simulation.

- Final Recommendations: Present a comprehensive set of recommendations for efficient nuclear waste disposal systems based on the research findings.

How ExtendSim will be used in this project.

ExtendSim will be the primary simulation tool used to build a detailed model of a nuclear waste disposal system. ExtendSim will allow for the representation of discrete events and the capturing of complex interactions between different stages of nuclear waste management, including transportation, storage, and disposal. ExtendSim’s capabilities in discrete event simulation, efficiency/utilization analysis, and scenario exploration will be critical in developing stress tests, conducting sensitivity analyses, and optimizing the system for enhanced performance. The tool's flexibility will enable the exploration of multiple scenarios, which will inform decision-making for improving operational efficiency.

What is unique about this project?

This research will offer one of the first comprehensive discrete event simulations focused specifically on the nuclear waste disposal from end-to-end operations. The combination of sensitivity analysis, stress testing, and scenario optimization within the nuclear waste management field is rare. Furthermore, by using advanced simulation techniques, this project will provide actionable insights not only for improving day-to-day operations but also for addressing long-term challenges such as waste volume increases and regulatory changes. The ability to model and optimize different scenarios will offer valuable strategies for improving safety and efficiency in nuclear waste disposition.

Why the interest in the indicated subject?

Nuclear waste management is a critical global challenge, with far-reaching consequences for safety, sustainability, and public health. My interest stems from the opportunity to contribute to a field where technological and operational improvements can have long-term environmental and societal impacts. Studying nuclear waste disposal operations can provide a model for future nuclear waste management systems globally, which aligns with my broader interest in sustainable environmental management and risk mitigation.

What impact will this research make to the existing current state of knowledge?

This research will provide novel insights into the nuclear waste management processes through the use of discrete event modeling. It will help set new standards for operational efficiency, safety, and cost-effectiveness in the handling and disposal of nuclear waste. The research findings can potentially be applied to other nuclear waste management facilities worldwide, promoting best practices in handling hazardous waste. Moreover, stress tests and sensitivity analyses will contribute to better preparedness for future challenges in nuclear waste management, including regulatory changes and the introduction of new waste streams.

Publications.

Andaverde, Alexis. "The Development and Analysis of Practical Decision Support Tool Implementations: Case Studies From Small Business to Large Government Enterprise." MS thesis. The University of Texas Rio Grande Valley, 2024.

Andaverde, Alexis, and Hiram Moya. "Development and Analysis of a Small-Business Inventory Control System; A Case Study." IISE Annual Conference and Expo. IISE, 2023.

Updates.

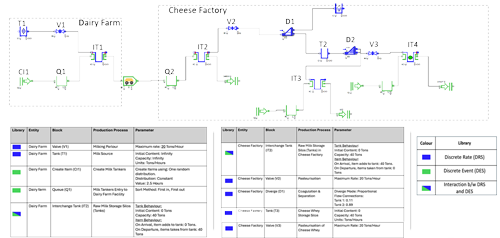

August 21, 2025 - This quarter, I focused on creating a current state of the nuclear waste processing system by structuring and implementing a Discrete Event Simulation (DES) model. The work involved developing a systematic framework for modeling key processes, incorporating various simulation components, and improving resource allocation strategies to enhance operational efficiency. Additional refinements were made to better represent system constraints and workflow dynamics.

The model has been structured to represent key aspects of the nuclear waste disposition process. It includes essential process flows, resource management strategies, and simulation components that allow for an analysis of system operations. Further refinements are planned to enhance accuracy and such as tracking of all necessary data points over multi simulation runs and implementing a schedule for workers in the system.

February 6, 2025 -This quarter, we focused on creating the current state of a nuclear waste processing system by structuring and implementing a Discrete Event Simulation (DES) model. The work involved developing a systematic framework for modeling key processes, incorporating various simulation components, and improving resource allocation strategies to enhance operational efficiency. Additional refinements were made to better represent system constraints and workflow dynamics.

February 6, 2025 -This quarter, we focused on creating the current state of a nuclear waste processing system by structuring and implementing a Discrete Event Simulation (DES) model. The work involved developing a systematic framework for modeling key processes, incorporating various simulation components, and improving resource allocation strategies to enhance operational efficiency. Additional refinements were made to better represent system constraints and workflow dynamics.

The model has been structured to represent key aspects of the nuclear waste disposition process. It includes essential process flows, resource management strategies, and simulation components that allow for an analysis of system operations. Further refinements are planned to enhance accuracy and such as tracking of all necessary data points over multi simulation runs, implementing a schedule for workers in the system, and determining a steady state of the system.

Optimization • Dairy Production Prediction

Use of AI tools and synergies in conjunction with operations research models

Use of AI tools and synergies in conjunction with operations research models

Osvaldo Palma Rubio

Doctorate of Mathematics

University of Lleida, Spain

Grant awarded: May 25, 2023

To be completed: September 1, 2026

Hypothesis.

The ability to predict cow's milk production has improved over the years with the use of data analytics tools. Many researchers mention the benefits of using simulation methods or artificial intelligence in the field of milk production. However, a combination of such techniques is not observed in the scientific literature, which presents an important research opportunity. Such a combination is expected to generate greater degrees of adjustment than by using the two techniques separately.

Project description.

- Year 1: Scoping review on dairy production prediction topics using artificial intelligence tools. Paper number 1.

- Year 2: Development of a discrete event simulation model that allows economic evaluation of productive policies and predictions of cow's milk production. Paper number 2.

- Year 3: Development of one or several neural networks for the prediction of cow's milk production and its comparison with traditional models. Paper number 3.

- Year 4: Development of a hybrid model that combines operational research methodologies and artificial intelligence for the productive improvement of dairy farms. Paper number 4.

Questions this research will answer.

How can the use of data analytics tools improve the prediction of cow's milk production?

How ExtendSim will be used in this project.

ExtendSim will be used to simulate the behavior of a dairy cattle and explore the net present value impact of different policies.

What is unique about this project?

According to a review of the current literature, there is no combination of simulation and artificial intelligence tools that try to make predictions about cow's milk production. The problem to be solved is important because the rapid growth of the world population will increase the demand for milk, therefore the use of technology will play an important role in being able to supply this demand.

Why the interest in the indicated subject?

The interest of this research is that it will be possible to study the production of cow's milk in order to meet the growing global demand for this important food through the use of data analysis tools.

What impact will this research make to the existing current state of knowledge?

Cow's milk production is important (Godfray et al., 2010). and depends on factors such as the productive potential of the animal and the conditions of exploitation. A common estimator of the current production of an animal is past production (time series) (Dongre et al., 2016), but there are other health or environmental factors that can condition the expression of this potential such as the presence of lameness and other diseases that can benefit from digital measurements of productive variables (Contla et al., 2021) such as body weight, diet control (composition and intake), early detection of pre- and postpartum diseases, assessment of body condition, etc. The main objective of the research is to explore the application of artificial intelligence (AI) tools for the analysis and prediction of productive variables such as cow's milk production. This study aims to be a contribution to data analytics (Data Analytics) combining traditional tools of operational research with AI.

Publications.

Currently in the last stage of preparation of my first publication consisting of the bibliographic review of this topic.

Updates.

Coming soon!

![]() Optimization • Warehouse Operations

Optimization • Warehouse Operations

Optimizing Warehouse Operations for Enhanced Efficiency and Demand Fulfillment

Optimizing Warehouse Operations for Enhanced Efficiency and Demand Fulfillment

Zeina Amr Abdel Moniem

Bachelor's Degree

Arab Academy For Science, Technology And Maritime Transport, Industrial & Management Engineering - Alexandria, Egypt

Grant awarded: January 2, 2025

To be completed: September 1, 2025

Hypothesis.

Efficient utilization of warehouse resources through simulation-based optimization can significantly improve operational efficiency, minimize resource waste, and ensure timely customer order fulfillment.

Project description.

This research focuses on leveraging simulation modeling to analyze and optimize warehouse operations. The study will identify inefficiencies in resource allocation, order picking, and storage systems. Using ExtendSim, various scenarios and layouts will be simulated to determine the most effective strategies for:

- Reducing picking times.

- Improving space utilization.

- Enhancing order processing rates.

- Minimizing operational costs.

Questions this research will answer.

- What are the key bottlenecks in the current warehouse operations?

- How can resource allocation be optimized to balance workloads and minimize idle times?

- What picking strategies (e.g., zone, batch, wave) yield the highest efficiency for varying demand levels?

- How does warehouse layout impact operational throughput and order accuracy?

How research strategy will be designed to help answer these questions.

- Data Collection: Gather data on current warehouse operations, including order volumes, resource allocation, and workflow patterns

- Model Development: Use ExtendSim to create a detailed simulation model of the warehouse.

- Scenario Analysis: Test various strategies for layout optimization, picking methods, and resource utilization.

- Performance Metrics: Measure key performance indicators such as picking time, order accuracy, throughput, and cost efficiency.

- Validation: Compare simulation results with real-world operations to validate the model.

How ExtendSim will be used in this project.

- Modeling Warehouse Processes: Develop a detailed simulation of warehouse workflows, including storage, picking, and packing.

- Scenario Testing: Simulate alternative layouts, resource allocation strategies, and order fulfillment techniques to evaluate their impact.

- Optimization: Use ExtendSim's built-in optimization tools to identify the best configurations for maximizing efficiency.

- Visualization: Create dynamic visual representations of the warehouse to understand resource flows and process bottlenecks.

What is unique about this project?

This project uniquely combines simulation modeling with a focus on real-time adaptability to changing customer demands and resource availability. It emphasizes optimizing end-to-end warehouse operations rather than isolated processes, offering a holistic approach to efficiency improvements.

Why the interest in the indicated subject?

The growing demand for efficient supply chain operations in e-commerce and retail highlights the need for robust warehouse systems. Optimizing these operations is crucial for ensuring timely delivery and reducing costs, aligning with my academic and professional interests in supply chain management and operations research.

What impact will this research make to the existing current state of knowledge?

The research will provide actionable insights into improving warehouse efficiency and customer satisfaction. It will also contribute to the development of adaptable, simulation-based methodologies for operational optimization in logistics and supply chain management.

Publications.

Coming Soon!

Updates.

Coming soon!

![]() Pharmaceutical Production Line Optimization • Increasing Efficiency, Reducing Bottlenecks, & Enhancing Quality

Pharmaceutical Production Line Optimization • Increasing Efficiency, Reducing Bottlenecks, & Enhancing Quality

Improving Production Line for Effervescent Sachets

Improving Production Line for Effervescent Sachets

Salma Ahmed Abdelghani

Bachelor's Degree in Engineering

Arab Academy For Science, Technology And Maritime Transport, Industrial & Management Engineering - Alexandria, Egypt

Grant awarded: January 2, 2025

To be completed: October 1, 2025

Hypothesis.

Optimizing the production line will increase efficiency, reduce bottlenecks, and enhance product quality.

Project description.

Study current inefficiencies, simulate potential improvements using ExtendSim, and evaluate results based on cycle time, throughput, and rejection rates.

Questions this research will answer.

- What are the main bottlenecks in the current process?

- How can variability and downtime be reduced?

- What improvements will maximize efficiency and cost-effectiveness?

How research strategy will be designed to help answer these questions.

- Collect real production data (e.g., process times, equipment performance).

- Simulate changes in ExtendSim to test solutions.

- Analyze and compare key performance metrics.

How ExtendSim will be used in this project.

Simulate the production process, test improvements, and visualize bottlenecks to optimize workflows.

What is unique about this project?

Focuses on improving production for effervescent sachets, a challenging product, using modern simulation tools.

Why the interest in the indicated subject?

Strong interest in optimizing pharmaceutical production to improve efficiency and product availability.

What impact will this research make to the existing current state of knowledge?

Will provide a practical framework for optimizing pharmaceutical manufacturing lines, reducing costs, and improving quality.

Publications.

No prior publications, but this project will contribute to my first.

Updates.

February 25, 2025 - We are currently working on a simulation project at Arvind Advanced Materials, focusing on optimizing production line efficiency through line balancing and defect analysis. We are using ExtendSim to model and test various scenarios for better workload distribution and defect reduction strategies.

So far, we have:

- Collected key production data, including SAM, defect rates, operator output, and rework data.

- Analyzed bottlenecks and inefficiencies within the line.

- Explored ExtendSim’s functionalities through available resources, including online tutorials and documentation, to better understand model creation.

Our mid-term review with our college faculty is scheduled for next week, on the 4th and 5th. Following this, we plan to start building and testing the simulation models, aiming for implementation next month.

Production Line Optimization • Line Balancing to Improve Production Efficiency

![]() Optimising Production Line: A Simulation model for style flexibility and machine reliability

Optimising Production Line: A Simulation model for style flexibility and machine reliability

Thiruvedhini R. & Arya Sukhadev

Bachelor's Degree in Fashion Technology

National Institute of Fashion Technology - Chennai, India

Grant awarded: November 22, 2024

To be completed: June 1, 2025

Hypothesis.

- Implementing a simulation-based line balancing model improves production efficiency by minimizing workflow disruptions, reducing defect rates, and accommodating operator absenteeism.

- Enhancing machine reliability and style flexibility through simulation leads to a significant reduction in production downtime and operational inefficiencies.

- Simulation-based adjustments in line balancing during operator absenteeism can mitigate its negative impact on production output and quality.

Project description.

- Develop a simulation model to balance production lines effectively.

- Minimize workflow disruptions caused by machine failures or operator absenteeism.

- Improve defect rates by analyzing the interaction between operator efficiency and machine reliability.

- Enable style flexibility to meet varying production demands efficiently.

Questions this research will answer.

- How does operator absenteeism disrupt workflow and affect productivity?

- Can simulation techniques predict and mitigate the impact of absenteeism on line performance?

- What are the optimal strategies for reallocating resources during operator absences?

- How does machine downtime affect workflow disruptions and defect rates?

- Can a simulation model account for machine reliability to create more robust production plans?

- What preventive measures can reduce the impact of machine failures on productivity?

How research strategy will be designed to help answer these questions.

- Collect data on absenteeism and its impact on production output.

- Analyze how tasks get delayed or bottlenecked.

- Simulate production workflows with absenteeism scenarios to observe disruptions.

- Build a simulation model to predict line performance under absenteeism.

- Test strategies like reallocating operators or adjusting workflows in the simulation.

- Identify operations most affected by absences.

- Simulate resource reallocation strategies, like cross-training or assigning floaters.

- Analyze data on machine failures and their effects on production and defects.

- Simulate downtime scenarios to see how it disrupts workflows.

- Identify operations where downtime causes the most defects or delays.

- Include machine reliability metrics (e.g., failure rates) in the simulation.

- Test how different maintenance plans affect production performance.

- Validate the simulation by comparing its predictions to real-world performance.

- Analyze failure causes and test preventive actions like maintenance schedules or backups.

- Simulate their impact on reducing downtime and maintaining productivity.

- Recommend cost-effective measures based on simulation results.

How ExtendSim will be used in this project.

- Simulate workflows, tasks, and dependencies.

- Test the impact of operator absences on productivity.

- Optimize strategies for reallocating operators and machines.

- Run "what-if" scenarios for absenteeism, machine failures, and style changes.

What is unique about this project?

- Combines absenteeism, machine reliability, and style flexibility in one model.

- Focuses on real-time disruptions like operator absence and machine breakdowns.

- Uses predictive models for optimizing workflows and minimizing defects.

- Adaptable to various styles and production setups.

Why the interest in the indicated subject?

We are interested in this subject because it combines real-world challenges in apparel manufacturing with innovative solutions through simulation. By addressing issues like operator absenteeism, machine reliability, and line balancing, the project offers practical ways to improve productivity and quality. The use of simulation tools like ExtendSim allows for testing and optimizing strategies in a controlled environment, making it possible to find effective solutions without disrupting actual production. This makes the project both impactful and adaptable to various manufacturing settings, enhancing efficiency and problem-solving in the industry.

What impact will this research make to the existing current state of knowledge?

The research on Optimizing Production Lines will help apparel manufacturers improve flexibility, machine reliability, and workforce efficiency. By using simulation models, companies can quickly adapt to changing styles, reduce machine downtime, and better allocate workers for higher productivity. This will lead to faster production, lower costs, and reduced waste. The research will also provide data-driven insights for better decision-making, helping businesses become more scalable, adaptable, and sustainable while staying competitive in the market.

Publications.

Coming soon!

Updates.

Coming soon!

![]() Warmup Analysis • Automated Method for Warmup Detection

Warmup Analysis • Automated Method for Warmup Detection

Development of a Tool to Automate Warmup Analysis in Discrete Event Simulation

Development of a Tool to Automate Warmup Analysis in Discrete Event Simulation

Harry Caffrey

Masters Degree

Dublin City University - Dublin, Ireland

Grant awarded: October 22, 2025

To be completed: June 1, 2026

Hypothesis.

Automating warmup period detection in discrete event simulation using statistical methods that will improve the accuracy and reliability of performance metrics by reducing bias from initial transient conditions.

Project description.

The project will develop a tool to automate warmup analysis in ExtendSim. It will implement statistical techniques such as Welch’s method, heuristic procedures, and randomization tests to identify when a simulation reaches steady state. The tool will be integrated into ExtendSim or linked via external scripts (R/Python), and validated on models like M/M/1 queues and production lines. Deliverables include the tool, simulation models, and a final report.

Questions this research will answer.

- When does a simulation reach steady state?

- Which statistical method provides the most reliable warmup detection?

- Does the method used depend on the system being run?

- How does removing the warmup period affect performance metrics?

How research strategy will be designed to help answer these questions.

I will implement and compare multiple warmup detection methods—such as Welch’s graphical method, heuristic procedures, and statistical tests—within ExtendSim. By running multiple replications of simulation models and analyzing time-series performance metrics, I will identify when the system reaches steady state. The tool will automate this process and output cleaned datasets for further analysis. Validation will be done using standard models like M/M/1 queues and production lines.

How ExtendSim will be used in this project.

ExtendSim will be used to build modular simulation models with logging and replication capabilities. It will serve as the platform for integrating warmup detection logic via external scripts linked to ExtendSim’s data export features. The tool will enhance ExtendSim’s analytical capabilities by automating a critical step in simulation analysis.

What is unique about this project?

This project addresses a well-known but often manually handled issue in simulation: identifying and removing the warmup period. By automating this process using statistical techniques, the project improves the reliability of simulation results. It also aims to produce a reusable tool that can be applied across various ExtendSim models, making it a valuable contribution to the simulation community.

Why the interest in the indicated subject?

I’m passionate about simulation as a method for understanding complex systems. The challenge of improving data quality and analysis in stochastic models is both intellectually engaging and practically important. Automating warmup detection combines statistical analysis with simulation modeling, which aligns with my interests in both areas.

What impact will this research make to the existing current state of knowledge?

The research will provide a validated, automated method for warmup detection in discrete event simulation, reducing bias and improving the credibility of performance metrics. It will help simulation practitioners make more informed decisions and could be extended to other platforms or domains, contributing broadly to simulation methodology.

Publications.

Coming Soon!

Updates.

Coming soon!