Is a new Industrial Revolution taking place? Quite possibly, yes. New tools to build smarter, leaner factories and explore innovative new products, materials, and techniques at a lower cost are emerging. Additive manufacturing, next-generation electronics, and advances in materials are upending the traditional manufacturing floor. How do you adjust?

Digital technology - simulation in particular - affords engineers and manufacturing professionals the ability to try out new technology and accelerate manufacturing innovation in novel ways never thought possible before.

Procter & Gamble (P&G) has used ExtendSim to "model all product lines - from soap to nuts" for design of equipment and production lines, scheduling, commerce, quality, etc. The models they build are used to interface with engineers who are not necessarily simulation experts, but can use if for analysis and design. Ultimately becoming simulation experts while using it because of ExtendSim's design.

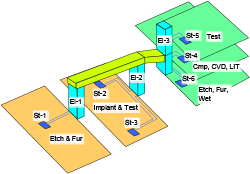

Complete Factory

Models

A huge model for DTE Energy that covered field, shop, office, and supply chain functions relating to electric metering equipment was built in ExtendSim in just 6 short weeks. Management was wowed by the animation level of the ExtendSim model during demonstrations. But the results were more impressive. With this model, DTE was able to predict the effects of potential regulations, weather, labor rules, and staffing levels. The model accurately predicted the type, number, and severity of problems that resulted a year later!

A major medical laboratory automation equipment producer sends its sales forces out to client sites with ExtendSim models to customize equipment for customers so the customer can see the proposed new equipment on their floor. This has dramatically increased the rate of sales successes. Then, the customer can use these same models to replicate their operations and explore opportunities to improve testing processes in lab analysis.

Dow Chemical Company performs reliability modeling in ExtendSim to identify and understand the impact of different failures on overall production capabilities in chemical plants. The model is used for understanding the key equipment components that contribute towards maximum production loss and for analyzing the impact of change policies, such as the installation of new equipment or an increased stock level for failure-prone components. A Failure Summary Report provides information for further phases of the analysis.

ExtendSim In Manufacturing

- Inventory and resource management.

- Managing Six Sigma/Lean initiatives.

- Scheduling and capacity planning.

- Procedure evaluation.

- Monte Carlo modeling.

- Capital investment analysis.

- Throughput and cycle time.

- Predict operational characteristics of projects.

- Measure average wait time and length of the queue.

- Batch and campaign sizes vs one-piece flow.

- Line balancing and routing changes.

- Speed prediction of a new motor in a robotic vehicle system checking its performance under varying conditions

- Analysis of bottlenecks in a seven-step manufacturing process.

Who is Using ExtendSim

For over two decades, P&G and Los Alamos National Laboratory (LANL) have collaborated in reliability engineering to create a proprietary set of tools (which includes ExtendSim) to understand the dynamics driving the production systems and provide solutions to accelerate throughput and productivity results.Reliability and throughput have increased 30 to 100% while scrap has been reduced by 20 to 50%.

For over two decades, P&G and Los Alamos National Laboratory (LANL) have collaborated in reliability engineering to create a proprietary set of tools (which includes ExtendSim) to understand the dynamics driving the production systems and provide solutions to accelerate throughput and productivity results.Reliability and throughput have increased 30 to 100% while scrap has been reduced by 20 to 50%. Grayrock & Associates LLC helped executives at an injection modeling plant determine if more equipment and an expanded space would be needed to meet increased production demands. The model substantiated that throughput could be increased by 25% without plant expansion or capital expenditures.

Grayrock & Associates LLC helped executives at an injection modeling plant determine if more equipment and an expanded space would be needed to meet increased production demands. The model substantiated that throughput could be increased by 25% without plant expansion or capital expenditures. Printing equipment manufacturer Polar Mohr developed a model that shows the productivity of their machines in a variety of applications. Sales engineers use this ExtendSim model to demonstrate the advantage of their equipment to their customers.

Printing equipment manufacturer Polar Mohr developed a model that shows the productivity of their machines in a variety of applications. Sales engineers use this ExtendSim model to demonstrate the advantage of their equipment to their customers. Johnson & Johnson commissioned the OpStat Group to create a simulation model which would examine current operations and develop solutions for the future for one of its large pharmaceutical plants. The model allowed the company to pre-test process changes and assist in the selection of techniques as part of a Lean Six Sigma program. The scope evolved from improvement and capacity projects to becoming integral to the ongoing planning and management process. Ultimately significant benefits ensued -- better utilization of personnel, accelerated delivery of value-added projects, and improved accuracy and timeliness of planning information -- allowing plant and supply chain management to evaluate options for sourcing and capacity within the plant and across the supply chain.

Johnson & Johnson commissioned the OpStat Group to create a simulation model which would examine current operations and develop solutions for the future for one of its large pharmaceutical plants. The model allowed the company to pre-test process changes and assist in the selection of techniques as part of a Lean Six Sigma program. The scope evolved from improvement and capacity projects to becoming integral to the ongoing planning and management process. Ultimately significant benefits ensued -- better utilization of personnel, accelerated delivery of value-added projects, and improved accuracy and timeliness of planning information -- allowing plant and supply chain management to evaluate options for sourcing and capacity within the plant and across the supply chain.- A Fortune 100 Consumer Products Company saved $1 billion across its operations by improving manufacturing reliability. Thus, allowing the company to introduce technology at a faster pace.

Working as a team, Crutchfield Corporation, a major consumer electronics catalog and Internet retailer, and Rust Management Technology used ExtendSim combined with ExpertFit to develop and validate a distribution center process simulation using Six Sigma techniques. Using insights developed through the simulation, Crutchfield Corporation estimates that it will save 15 to 20 times the cost of the project in the first year after deployment.

Working as a team, Crutchfield Corporation, a major consumer electronics catalog and Internet retailer, and Rust Management Technology used ExtendSim combined with ExpertFit to develop and validate a distribution center process simulation using Six Sigma techniques. Using insights developed through the simulation, Crutchfield Corporation estimates that it will save 15 to 20 times the cost of the project in the first year after deployment.- An automotive equipment manufacturer optimizes the design of its suspension systems by comparing a model’s simulated results to real-time data transmitted by sensors on automobiles.

- A New Zealand pulp and paper mill models their integrated pulp mill, recycle facility, and sack kraft machine to determine the optimum mix of products and grades for specific economic conditions. This mill now boasts bleached softwood kraft production costs in the bottom quartile worldwide.

- A polyethylene producer looked to determine the size of the intermediate tank between the ethylene production and its later polymerization. The tank allowed to free the two sectors of the production when one of them stopped for lack of supply or raw materials or flaws in the equipment. Incremental sizes of the tank allowed a bigger independence between the processes with a concrete increase of the PE production; this trade-off (size/cost of the tank vs. expected incremental outcome) was subject to scrutiny using simulation, allowing to feed a complementary economic analysis.

- An industrial company wanted to determine the optimal use of a worker serving a pool of 6 (six) wiring machines. The purpose of the study was to assign more tasks to the same person because the demand of attention of machines did not consume the entire person's available time. Surprisingly, the recommendation coming from the simulation model was to add a second worker to the same sector. This would result in a very low use of manpower, but a very important increment of the machines' output due to the interference of the flaws of the different machines along time, causing two or more machines were stopped waiting of the attention of the crew.

IBM Global Services Australia built a print distribution model in ExtendSim to determine delivery times, resource requirements, duty rosters, and capacity to meet Service Level Agreements during Summer Olympic games.

IBM Global Services Australia built a print distribution model in ExtendSim to determine delivery times, resource requirements, duty rosters, and capacity to meet Service Level Agreements during Summer Olympic games.- $100 million annual savings by an international paper manufacturer who used ExtendSim to improve the effectiveness of their capital investments.

- A tobacco manufacturing plant in Augustow, Poland built an ExtendSim model to support the triplication of production volume within a five year time period as an answer to the entrance of Poland in the European Economic Community.

- ExtendSim has been used to model wing production for 737s.

- PCB and semiconductor facilities.

- Consumer product manufacturers.

- Aerospace operations.

Case Studies

Akram Gamal, Jana Mohamed, Maram Kamal, Mohamed Anis, and Omar Shehab • Arab Academy for Science, Technology and Maritime Transport

August 2025

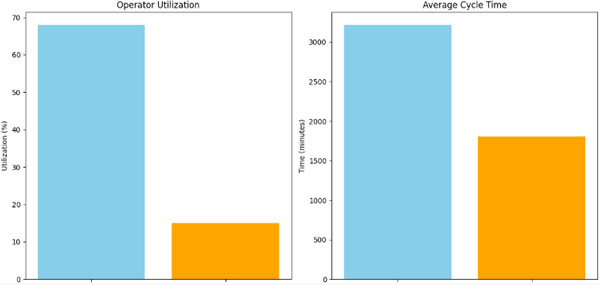

The implementation of a real-time RFID-based inventory management system significantly improved operational efficiency at a warehouse previously reliant on manual pallet tracking and verbal coordination. The old system caused delays, overworked staff, and poor resource utilization. With RFID integration, forklift operators now retrieve pallets directly from digital production plans, eliminating manual searches and streamlining communication. An ExtendSim model and Multi-Criteria Decision-Making Analysis (MCDM) helped select optimal RFID components, balancing performance and cost.

The results were striking: operator utilization dropped from 68% to 15%, and average cycle time was reduced by 44%. These improvements align with Industry 4.0 principles, enhancing traceability, visibility, and data-driven decision-making. The project demonstrates how digital transformation can lead to smarter, faster, and more reliable inventory processes, better equipping operations to meet modern business demands.

Eoin Glennane • Dublin City University

June 2021

This paper presents a closed loop supply chain for a reusable, deteriorating tool. The tool is used in a manufacturing process on an item in a linear supply chain. A model is created for the linear item supply chain and the tools closed loop supply chain to analyse the interactions between them and various input parameters so that output responses of the system can be modelled. Three approaches are taken to model the system, a brute force factorial design, a modified version of a Latin hypercube space filling design, and a fast flexible space filling design. It is found that all three methods Design Expert, RLHC, and FFFD, accurately predict the response with the least amount of input. Space filling designs should be used if more factors are needed as they minimise the total amount of simulations needed to produce an accurate model.

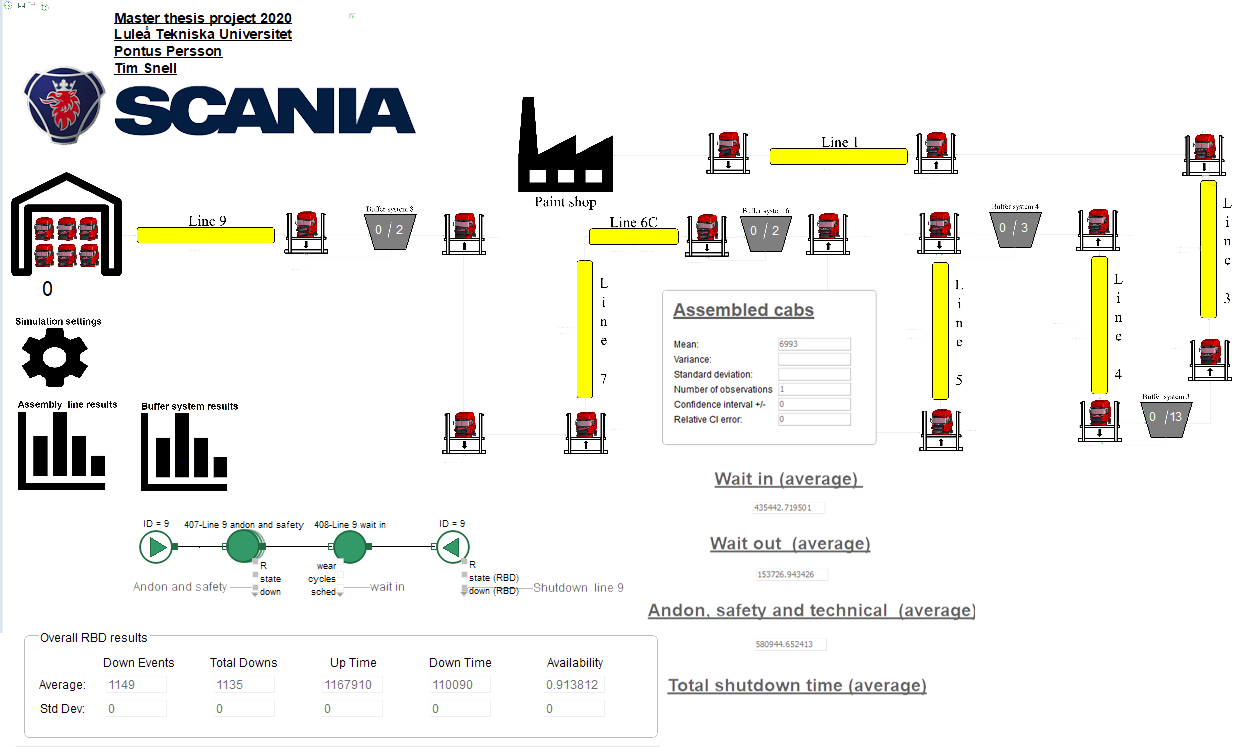

Application of Discrete Event Simulation for Assembly Process Optimization • Buffer and Takt Time Management

Pontus Persson & Tim Snell • Luleå Tekniska Universitet

May 2020

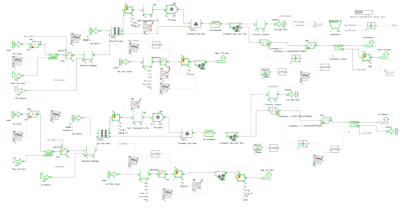

A master thesis within mechanical engineering performed by two students has been conducted at Scania in Oskarshamn. The purpose has been to investigate if Discrete Event Simulation using ExtendSim can be applied to increase Scania's assembly productivity. The objective was to investigate how buffer systems could be managed by varying the amount of buffers and their transport speed. Assembly line takt times with regard of their availability was also investigated. The method of approach was to build a simulation model to gain valid decision making information regarding these aspects. Process stop data was extracted and imported to ExtendSim where the Reliability library was used to generate shutdowns.

Comparing 24 sets over 100 runs to each other a median standard deviation of 0,91 % was achieved. Comparing the total amount of assembled cabs over a time period of five weeks with the real time data a difference of 4,77 % was achieved. A difference of 1,85 % in total amount of shutdown time was also achieved for the same conditions.

The biggest effect of varying buffer spaces was for system 6A. An increasement of up to 20 more assembled cabs over a time period of five weeks could then be achieved. By increasing all the buffer transport speeds by 40 %, up to 20 more assembled cabs over a time period of five weeks could be achieved. A push and pull system was also investigated where the push generated the best results. A 22 hour decreasement of total shutdown time and an increasement of 113 more assembled cabs over a time period of five weeks could be achieved.

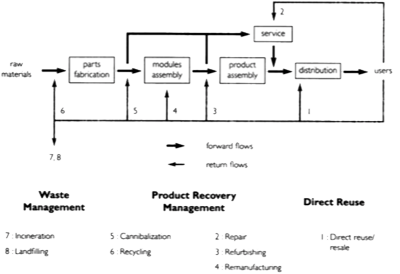

Performance Analysis and Development of Pull-Type Production Control Strategies for Evolutionary Optimisation of Closed-Loop Supply Chains

Jonathan Ebner • Dublin City University

January 2018

This project establishes a Closed-Loop Supply Chain (CLSC) design that is analysed through a series of simulation models, aimed at defining the highest performing production control strategy, whilst considering multiple related variables on both the forward and reverse flow of materials in manufacturing environments. Due to its stochastic nature, the reverse logistics side of the CLSC represents an increased source of variance for the inventory management and control strategies as it implies the erratic supply of returned materials, in addition to the very random customer demand, hence with highly variable inputs on both sides of the productive system, intrinsically inherent to this line of research. The dynamic allocation policies, particularly the Dynamic Hybrid Extended Kanban CONWIP special case (DNC HEKC-II), throughout the research space in consideration, evidenced very superior production control performance overall.

El Astillero 4.0: Modelado y Simulación del Astillero de Navantia - Ferrol

Mar Cebral Fernández, Marcos Rouco-Couzo, Marta Quiroga Pazos - UMI Navantia, UDC; Rafael Morgade Abeal - Navantia Ferrol; Alejandro García del Valle & Diego Crespo-Pereira

Universidade da Coruña.

Shipbuilding is one of the most complex existing manufacturing processes. The large number of operations necessary to produce the parts that make up a vessel coupled with the need to synchronize multiple workflows and numerous resources where serial production is practically non-existent, make the management of such a production system very difficult. Simulation is an extremely powerful tool for the decision-making process to test and evaluate different scenarios, to efficiently plan future investments, to determine the allocation of resources, and to drastically reduce the risks of making incorrect decisions. This case study uses ExtendSim to model the manufacturing process of a frigate from the shipyard of Navantia Ferr to minimize the uncertainties of shipbuilding.

Oladipupo A. Olaitan, B.Sc., M.Sc.

Dublin City University - School of Mechanical & Manufacturing Engineering

January 2016

In multiproduct manufacturing systems, it is difficult to assure that an optimised setting of a pull production control strategy will be able to maintain its service level and inventory control performances. This is because the competition for resources among products is liable to make them affect the service levels of one another. By comparing different pull strategies, research presented in this paper has observed that tightly coupled strategies are able to maintain lower amount of inventory than decoupled strategies, but they do so at the detriment of service level robustness. As a result, tightly coupled strategies are better suited to manufacturing environments with low variability, while decoupled strategies are more robust in high variability environments. Here, robustness is a measure of how well a strategy is able to minimise the drop below its original optimised service level when the initial system conditions change. Furthermore, the Kanban allocation policy applied under a strategy plays a major role in its ability to manage the performances of multiple products. Experimental results show that the Shared Kanban Allocation Policy (SKAP) keeps a lower amount of inventory than the Dedicated Kanban Allocation Policy (DKAP), but it is more susceptible to the variability in the demand or processing times of one product impacting the service level of another. Therefore, a Hybrid Kanban allocation policy (HKAP) that combines both the DKAP and the SKAP has been implemented. This approach considers products’ demand and processing time attributes before categorising them into the same Kanban sharing group. The results of the implementation of the HKAP show that it can keep as low inventory as the SKAP and avoid products impacting the service levels of one another. Additionally, it offers a better approach to managing large multiproduct systems, as the performances of product groups can be differentially managed through the combination of Kanban sharing and dedication policies. Lastly, the observations on the performances of strategies and policies under different system conditions can be used as a framework through which line designers select strategies and policies to suit their manufacturing system.

Gwenola Jaouen

Aluminum International Today

July/August 2011

Designing a casthouse for billet is a complex activity. The billet casthouse must be properly sized to optimize the metal flow, and continuously feed the homogenization shop, while bearing in mind that oversizing adds no value and is costly. To solve this problem, it is necessary to accurately analyze the operations of the casthouse in real time and this requires a discrete simulation model.

Gwenola Jaouen of Rio Tinto Alcan Smelter Technology in Voreppe Cedex, France developed an ExtendSim model containing a library that includes all the necessary equipment: conveyors, continuous and batch furnaces, and finishing stations. The model was used to design an expended casthouse which requests the management of complex product mixes and which challenges the robustness and flexibility of the installation. By combining this model with the metal flow sizing model, it was possible to validate the performance of the design and its impact on casthouse operation. This resulted in a shop designed for customer needs, at optimal cost.

Project details were presented at TMS (The Minerals, Metals and Materials Society) 2011 Annual Meeting & Exhibition in March of 2011 at the San Diego Convention Center, San Diego, California.

Vicente González, Luis Fernando Alarcón, and Pedro Gazmuri • Pontificia Universidad de Católica de Chile

July 2008

Variability in production is one of the largest factors that negatively impacts construction project performance. A common construction practice to protect production systems from variability is the use of buffers (Bf). Construction practitioners and researchers have proposed buffering approaches for different production situations, but these approaches have faced practical limitations in their application.

In Multiobjective Design of Work-In-Process Buffer for Scheduling Repetitive Building Projects, a multiobjective analytic model (MAM) is proposed to develop a graphical solution for the design of Work-In-Process (WIP) Bf in order to overcome these practical limitations to Bf application, being demonstrated through the scheduling of repetitive building projects. Multiobjective analytic modeling is based on Simulation–Optimization (SO) modeling and Pareto Fronts concepts. Simulation–Optimization framework uses Evolutionary Strategies (ES) as the optimization search approach, which allows for the design of optimum WIP Bf sizes by optimizing different project objectives (e.g., project cost, time and productivity). The framework is tested and validated on two repetitive building projects. The SO framework is then generalized through Pareto Front concepts, allowing for the development of the MAM as nomographs for practical use. The application advantages of the MAM are shown through a project scheduling example. Results demonstrate project performance improvements and a more efficient and practical design of WIP Bf. Additionally, production strategies based on WIP Bf and lean production principles in construction are discussed.

Jim Curry

OpStat Group, Inc.

June 6, 2006 APICS eNews

Brief introductory article discussing the key element in lean implementation: simulation. Simulation has been used successfully in factory floor improvement, inventory management, capacity analyses, and process design. Benefits such as the following are not unusual.

- Postponing final packaging results in 30 percent inventory reduction with substantial service improvement to more than 97 percent.

- Shift/work center change allows reduction of staff from 7 to 6 days per week.

- Adding staff to a bottleneck work center reduces overall number of workers by 10 percent.

- Synchronized operations reduce cycle time from 18 to 13 weeks.

Jim Curry

OpStat Group, Inc.

This paper presents a case study where simulation was used to convert from a manufacturing resource planning (MRP) based push process to a demand-driven pull process in a single plant operation factory floor. Simulation is a software program that allows one to visually see and measure how processes perform over time, including materials, information and financial flows, and how probabilistic variables impact them

Procter & Gamble in conjunction with Los Alamos National Laboratory

Energy.gov

October 2011

Procter & Gamble partnered with the Energy Department's Los Alamos National Laboratory (LANL) in the 1990s. LANL scientists helped P&G engineers develop simulations to improve the reliability of P&G's complex production lines. P&G's 150 facilities worldwide saw a 44 percent increase in plant productivity and 30 percent increase in equipment reliability since they started using the software.

The pairing of the lab and corporations' data led to the creation of simulation software called Reliability Technology in 1993. With the software, engineers can configure both the machines and their maintenance schedules based on reliability. In addition, engineers could foresee and possibly avoids product jams, intervals of a component breakage or variations in a machine speeds. In other cases, engineers could triage the production line. Large-scale implementation of the technology helped save P&G $1 billion in manufacturing costs, according to Procter & Gamble. These cost-saving benefits are applicable towards production lines across the manufacturing sector.

Yinhui Ao and Zhenxin Wu, Faculty of Mechanical and Electrical Engineering, Guangzdong University of Technology, Guangzhou, China

Applied Mechanics and Materials (Volume 109)

October 2011

LED (Light Emitting Diode) has many excellent features as a new lighting device and has been widely used by far. The structure and light-emitting principles are introduced in this paper. The LED manufacturing process is explained and shown dynamically. A processing line is modeled and simulated in ExtendSim. The simulation result is analyzed and the processing line is balanced. Throughput is improved with the simulation.

Gray McQuarrie of Grayrock & Assocaties

The PCB Magazine

July 2013

"Some years ago I walked into a PCB facility that was making very complex HDI product, but wasn’t making any money. By focusing on constraining the WIP (CONWIP), identifying and focusing on the production bottlenecks to help develop a scheduling paradigm, working side by side with the operators to devise their own rules for dispatching jobs, and implementing a production pull system using Kanbans, profitability soared, WIP was reduced by two-thirds, and the standard production lead time decreased from 15 to four days with one-day quick-turns."

Dr. Donald W. Collins, Luc D’Arcy Collins, and Bob Franklin

Conference on Modeling and Analysis of Semiconductor Manufacturing

2002

Logic and assumptions used in building a simulation model of an Automated Material Handling System (AMHS) for an eight inch Wafer FAB are presented in this paper. The ExtendSim model built for this project includes the ability to make changes to the area stocker layout, number of area stockers, number of loops, number of cars, and/or the number of Lot moves. This model is used to determine if the Area Stockers can handle the quantities of Lots per hour required by From-To-Table "customer" requirements.

Kevin T. Higgins

Food Engineering Magazine

August 2001

Packages that accurately emulate the hybrid processes that characterize food and beverage manufacturing are making simulation more than just a snazzy presentation tool for upper management. Virtual Engineering's New Frontier describes users roughing out their production and packaging lines on screen to gain insight into the dynamics of their lines and where and why bottlenecks occur.

Videos

The key to discrete event modeling is the construction of a flow diagram using blocks to represent the problem's operations and resources. The most common discrete event model involves the handling of one or more waiting lines or queues, such as those found in supermarkets, factories, banks, etc.

Created by Grayrock & Associates, this video discusses a discrete event model built in ExtendSim to look at issues of dealing with finite plant capacity. He also touches on design of experiments and neural networks.

Download Paper

Download Paper Download ExtendSim Model

Download ExtendSim Model

Go to Report

Go to Report