Moving products and materials isn’t as easy as it once was. Globalization has dramatically impacted the way companies do business. Consumers want products faster, and the marketplace is under pressure to meet those demands. So it is imperative organizations operate at maximum efficiency to remain competitive and profitable.

Simulating your strategy with ExtendSim makes sure everything and everyone gets where they need to be when they need to be there.

Transportation

Logistics

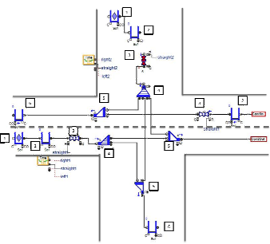

During a major rehabilitation project for a railway tunnel in southern Norway, capacity of the railway's track was scheduled to be reduced, plus velocity restrictions enforced in certain parts of the tunnel. DNV Asset Integrity Management performed a regularity and capacity study to investigate whether the new capacity and velocity restrictions would cause major problems for the operation of this busy part of the railway system. Based on the ExtendSim model created, DNV was able to give the railway operator detailed advice on whether the solution was feasible for the refurbishment period and how details should be solved to minimize disturbances.

Product

Flow

Over-utilized inventory locations at one of its grocery products facilities was causing problems with Hormel Foods Corporation's product flow. Product mix and number of supply items had grown creating an imbalance in storage locations for the inventory. Inputing data from a sampling of time, they used ExtendSim to model the different systems that were supplying and demanding material from bay locations at various rates, quantities, and shifts of operation. Hormel was able to determine the best alternative solution while verifying adequate inventory turns, minimizing equipment and material handling costs, and meeting capacity requirements.

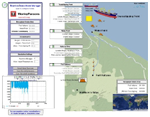

Following a scoping study which identified a range of transportation options, high level pit-to-port models of the Matthews Ridge Manganese Project in Guyana, South America were simulated in ExtendSim. The purpose was to address critical strategic questions, such as dredging requirements (both in the transporting river and near shore), the need for navigation aids for night time barging, plus barge/tug fleet size requirements. In addition to resulting in multi-million dollar savings, the model assesses a range of trade growth scenarios.

Using ExtendSim to build virtual integrated (operations and logistics) models that consider all physical intermodal processes to measure the actions, effects, and responses within a system, WorleyParsons is able to validate design, assess sensitivities, and quantify operational risk to project - not just local risks to each process, but all interconnected risks through the logistics chain. Their models improve the quality of decisions, identifies bottlenecks, and assists with investment strategy for their clients by providing quantitative decision support and systems analysis through discrete event simulation. Their quantified recommendations have positively impacted client operational design to the order of tens of millions of dollars.

Logistics, Supply Chain, and Transportation Modeling with ExtendSim

- Acquisition, sustainability, integrated logistics, collaborative supply chains, scheduling, service level, performance measurement, risk management, and process optimization.

- Global logistics management.

- Efficiently integrate suppliers, factories, warehouses and stores so that merchandise is produced and distributed in the right quantities, gets to the right locations and at the right time, and while minimizing total system cost.

- Six Sigma/Lean initiatives.

- Emergency planning.

- Airport baggage and terminal operations modeling.

- Help determine the optimal level of safety stock and cycle stock for supply chain processes.

- Monitor freight movement to determine operational efficiency and rationalize planning decisions

- Logistics of container handling to improve system efficiency.

- Pit to port mining supply chain simulations.

- Impacts of regional urban development patterns on the performance of transportation infrastructure are being evaluated with ExtendSim.

Who is Using ExtendSim

DNV GL modeled a liquefied natural gas (LNG) supply chain in ExtendSim to determine the feasibility of an entire supply chain (gas→LNG→ship load→gas market). This complex case study examined this transport chain with regard to its export market and the number and type of ships. Details included the availability of an offshore installation (including the mobilization of vessels), an LNG onshore plant, plus shipping and regassification.

DNV GL modeled a liquefied natural gas (LNG) supply chain in ExtendSim to determine the feasibility of an entire supply chain (gas→LNG→ship load→gas market). This complex case study examined this transport chain with regard to its export market and the number and type of ships. Details included the availability of an offshore installation (including the mobilization of vessels), an LNG onshore plant, plus shipping and regassification. Baosteel Technology Center/Automation Institute, the largest iron and steel company in China and a global 500 company, used ExtendSim in a melt iron transportation logistics analysis project. This was the first discrete event simulation project Baosteel built with an off-the-shelf commercial tool. Edgestone Information Technologies Co., Ltd. teamed with the Baosteel Technology Center to lead the project in modeling and analytical experiments producing meaningful results in their capacity expansion evaluation project. Baosteel is impressed with the scalability of ExtendSim and the results of this project.

Baosteel Technology Center/Automation Institute, the largest iron and steel company in China and a global 500 company, used ExtendSim in a melt iron transportation logistics analysis project. This was the first discrete event simulation project Baosteel built with an off-the-shelf commercial tool. Edgestone Information Technologies Co., Ltd. teamed with the Baosteel Technology Center to lead the project in modeling and analytical experiments producing meaningful results in their capacity expansion evaluation project. Baosteel is impressed with the scalability of ExtendSim and the results of this project. Huegin Consulting Group created a dynamic simulation of a Fly-In Fly-Out aviation network for a global Gold Mining company designed to help quantify and assess the relative likely performance of different aviation charter tenderers in terms of passenger movements and cost.

Huegin Consulting Group created a dynamic simulation of a Fly-In Fly-Out aviation network for a global Gold Mining company designed to help quantify and assess the relative likely performance of different aviation charter tenderers in terms of passenger movements and cost. Worley Parsons created a supply chain simulation of a complex logging operation in New Zealand focusing on its port operations to assist in assessing throughput improvement options. This project undertook significant historical data modelling to create a robust, stochastic truck and docket arrivals generator that feeds a detailed port-side storage and log handling simulation. The simulation enables future annual target throughput to be defined, and from this, a realistic logging and shipping operation is simulated. It enables detailed quantitative assessment of the likely impacts of alternate business improvement options. This model uses ExtendSim's Advanced Resource Management capability in an a pseudo-object oriented model architecture.

Worley Parsons created a supply chain simulation of a complex logging operation in New Zealand focusing on its port operations to assist in assessing throughput improvement options. This project undertook significant historical data modelling to create a robust, stochastic truck and docket arrivals generator that feeds a detailed port-side storage and log handling simulation. The simulation enables future annual target throughput to be defined, and from this, a realistic logging and shipping operation is simulated. It enables detailed quantitative assessment of the likely impacts of alternate business improvement options. This model uses ExtendSim's Advanced Resource Management capability in an a pseudo-object oriented model architecture. BP Amoco used ExtendSim to simulate seasonal variations in their pipeline and for the tracking of inventory. Their combined continuous and discrete event model looked at the effects of fleet changes, tank storage, and pipeline. It modeled loading and unloading procedures as well as ballast water treatment.

BP Amoco used ExtendSim to simulate seasonal variations in their pipeline and for the tracking of inventory. Their combined continuous and discrete event model looked at the effects of fleet changes, tank storage, and pipeline. It modeled loading and unloading procedures as well as ballast water treatment. Wagner SprayTech manages their ever-growing supply chain with an ExtendSim model showing stores, distribution centers, and assembly line constraints to eradicate delays of their consumer and professional paint application tools.

Wagner SprayTech manages their ever-growing supply chain with an ExtendSim model showing stores, distribution centers, and assembly line constraints to eradicate delays of their consumer and professional paint application tools.- An oil and gas infrastructure simulation was created to test downstream storage options and strategies for tank management and ship prioritization to maximize production flow and minimize ship waiting time. The model included upstream feed sites and storage for transferring product along a 650 kilometer pipeline to a downstream storage site with multiple storage tanks, plus a shared wharf. The 16 year time horizon simulation also includes a detailed shipping representation with daylight navigation restrictions and background traffic competing for the berth.

- Airport security agencies use ExtendSim to evaluate the effects on passenger flow of new airport security checkpoint equipment and procedures.

A detailed coal supply chain simulation was built by Wave International to test candidate materials handling facilities and stockpile management strategies. The simulation was fed by the mine plan, and each parcel of coal was tracked through the supply chain until blending in the MHF upon stacking, then managed reclaim blending upon train loading to dispatch trains as close to grade as possible.

A detailed coal supply chain simulation was built by Wave International to test candidate materials handling facilities and stockpile management strategies. The simulation was fed by the mine plan, and each parcel of coal was tracked through the supply chain until blending in the MHF upon stacking, then managed reclaim blending upon train loading to dispatch trains as close to grade as possible. IBM Global Services Australia built a print distribution model in ExtendSim to determine delivery times, resource requirements, duty rosters, and capacity to meet Service Level Agreements during Summer Olympic games.

IBM Global Services Australia built a print distribution model in ExtendSim to determine delivery times, resource requirements, duty rosters, and capacity to meet Service Level Agreements during Summer Olympic games.- A major oil company oil company used ExtendSim to validate the process design for a $5.7 billion capital project.

Case Studies

Modelling Mass Crowd Using Discrete Event Simulation: A Case Study of Integrated Tawaf and Sayee Rituals during Hajj

Almoaid Owaidah, Doina Olaru, Mohammed Bennamoun, & R. Nazim Khan • Department of Computer Science and Software Engineering, Business School, and the Department of Mathematics and Statistics at the University of Western Australia

Ferdous Sohel • Discipline of Information Technology, Murdoch University

IEEE Xplore • Volume 9

May 2021

Hajj is a mass gathering event that takes place annually in Makkah, Saudi Arabia. Typically, around three million people participate in the event and perform rituals that involve movement within strict space and time restrictions. Despite efforts by the Hajj organizers, such massive crowd gatherings and movement causes overcrowding problems at the Hajj sites.There are are two important rituals that are performed by all the pilgrims at the same venue on the same day - Tawaf, followed by Sayee. Several previous simulation studies on Hajj have focused on the rituals individually. This paper studies both events jointly, rather than separately. Using ExtendSim, the authors integrate the Tawaf and Sayee rituals into one model. The validated model was applied to a wide range of scenarios where different percentages of pilgrims were allocated to the various Tawaf and Sayee areas. The effect of such allocations on the time to complete Tawaf and Sayee indicate strategies for managing these two key Hajj rituals.

Tobias Reggelin, Sebastian Lang, and Christian Schauf

Journal of Simulation

November 12, 2020

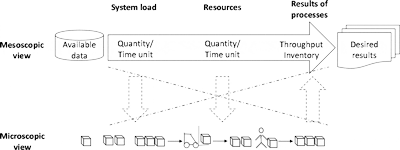

The application of mesoscopic discrete rate simulation models for two typical planning tasks in the automotive industry are demonstrated by the authors to illustrate the capability of this modelling class to meet the requirements of logistics and production planners by providing more accurate simulation results. Typically, planning engineers solve these tasks with detailed microscopic simulation models because of the availability of object-based discrete event simulation tools in the automotive industry, which leads to complicated and slow models. However, the combined use of discrete rate and discrete event modeling in mescoscopic models can represent logistics flow processes on an aggregated level through piecewise-constant flow rates by applying the discrete rate simulation paradigm instead of modelling individual flow objects leading to fast model building and computation.

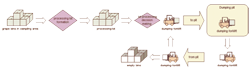

Frederick Abiprabowo • University of Pennsylvania

December 2012

Studies of cross-dock fundamentals typically take a high-level perspective and discuss the issues of cross-docking in relation to a company’s distribution process, management, etc. Cross-docking can also be viewed as a method in the management of a supply chain. Distribution planning problems pertain to scheduling of trucks, vehicle routing, and network navigation. This report describes how simulation can be used as a design and validation tool for cross- docking facilities. It contains a step-by-step walkthrough of the model, testing parameters, and its results are included. Finally, some ideas for the future model are proposed.

Award-Winning Project

During the INFORMS Annual Conference 2013, the design team of Frederick Abiprabowo, Napat Harinsuit, Samuel Lim, and Willis Zhang, all from the University of Pennsylvania, were awarded the Undergraduate Operations Research Prize. This competition is held each year to honor a student or group of students who conducted a significant applied project in operations research or management science, and/or original and important theoretical or applied research in operations research or management science, while enrolled as an undergraduate student.

Their paper Designing a Simulation Tool for Commercial Cross-Docking Application uses ExtendSim to dynamically replicate the operations of a large cross docking facility. The prototype model serves as a tool that enables cross-dock operators to evaluate assignment strategies in a risk-free, costless environment.

Zongze Chen • University of Pennsylvania

May 2010

In collaboration with the National Retail Systems (NRS) North Bergen facility who receives goods from multiple vendors, sorts, and loads them onto outbound trailer trucks for a number of retail stores, a simulation model of two cross-docks in operation of their New Jersey facility was developed. The final report describes how simulation helps ensure success of cross-docking systems by determining optimal routing costs. Modeling methods and issues are also discussed as they apply to cross-docking. This report includes discussion of the actual processes employed by NRS, description of ExtendSim models developed, simulation results and comparisons, and conclusions.

1Point2 - Sassenage, France

Simulation helped Air France provide better connection rates for passengers traveling through Roissy-Charles-de-Gaule airport. Plus it enable them to reorganize their shuttle timetables to provide lower costs and better service to it passengers

Gray McQuarrie, Grayrock & Associates

The PCB Magazine

September 2012

Does it really make sense to roll the dice with an important customer order, just because of the inherent unreliability of your metal finishing operation? If so, it may be time for you to change the game—today. In the October 2012 issue of The PCB Magazine, Gray MacQuarrie, president of Grayrock & Associates, introduces an ExtendSim model that could be used to illustrate cost to a business when a worst-case scenario happens and how you could best handle the situation with your customer.

No DAM Extras…Like, Ever!

Gray McQuarrie, Grayrock & Associates

The PCB Magazine

October 2012

How we manage our scrap events determines whether our business thrives or dies. Consider a policy to start absolute-lot quantities, which means, no extras, ever. In the October 2012 issue of The PCB Magazine, Gray MacQuarrie, president of Grayrock & Associates, uses ExtendSim to illustrate the option of restarting jobs in which you start absolute-lot quantities—no extras—even though this requires disciplined execution and a tightly timed and reliable production process. This option could make your operation extremely profitable—if you can do it.

George Mason University Consortium

GMU, Department of CEIE and Department of Geography and Geo Information Science; Rutgers University; CSC Advanced Marine Center, Washington DC; GeoEye Incorporated; DLR, Germany

June 2012

The Marine highway system is in the forefront of alternate transportation concepts considered for meeting future freight capacity requirements. Moving freight by waterways reduces the impact of highway freight on the environment, saves transportation related fuel consumption, and reduces infrastructure maintenance cost, specifically on pavements and bridges. The system has the potential for complementing and increasing the productivity and performance of other intermodal systems.

A flexible modeling process was developed for analyzing diversion of freight from highways to waterways, interlinking results from the highway diversion model with a scalable waterway (marine) model. The results enable estimation of the cost and other advantages of the marine highway system. The quantification of direct and indirect benefits will guide the initial decision making process for planning marine highway. The model is constructed to be flexible and scalable for application to any waterway and highway system for rapid comparisons of advantages to support first line decision making.

The project developed methods to compare potential cost savings in marine highways by coupling the following three modeling and analysis processes:

- A highway model for freight flow leading to the ports

- A waterway model for marine transportation

- A drayage freight flow analysis system.

The marine highway freight system (MHFS) offers the opportunity for increasing freight capacity and relieving highway congestion with low infrastructure investments. The GMU Consortium study showed that planning of marine highways can be accomplished cost effectively using results of model analysis and by applying emerging CRS&SI tools.

Framework for Airport Outbound Passenger Flow Modelling

Sultan Alodhaibi, Robert Burdett, Prasad KDV Yarlagadda - Queensland University of Technology

Procedia Engineering, Volume 174, pp. 1100-1109

2016 Global Congress on Manufacturing and Management

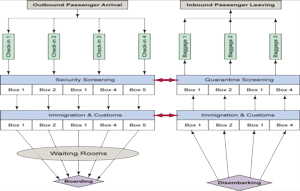

This paper focusses upon passenger flow issues within airport terminals and includes all activities occurring between curb-side and boarding. To improve passenger flow and associated planning activities, a simulation framework is developed using Discrete-Event Simulation (DES) using ExtendSim 9.2 simulator software. The model can be used to evaluate the efficiency of the outbound operational processes including check-in, security screening, immigration & custom and boarding. It can also assist management to identify potential bottlenecks in the system. The main input of the model is the flight schedule. A case study of the Brisbane international airport was analysed.

>

>Leonardo G. Hernandez-Landa, Miguel L. Morales-Marroquin, Yasmin A. Rios-Solis, Romeo Sanchez Nigenda; Autonomous University of Nuevo Leon

•

Chapter from the book Applied Simulation and Optimization: In Logistics, Industrial and Aeronautical Practice (pp.303-319)

April 2015

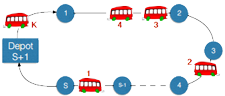

One of the most annoying problems in urban bus operations is bus bunching, which happens when two or more buses arrive at a stop nose to tail. Bus bunching reflects an unreliable service that affects transit operations by increasing passenger-waiting times. This work proposes a linear mathematical programming model that establishes bus holding times at certain stops along a transit corridor to avoid bus bunching. The authors' approach needs real-time input, so a transit corridor is simulated and a mathematical model applied to the data generated. Thus, the inherent variability of a transit system is considered by the simulation, while the optimization model takes into account the key variables and constraints of the bus operation. Most of the literature considers quadratic models that minimize passenger-waiting times, but they are harder to solve and therefore difficult to operate by real-time systems. On the other hand, this methodology reduces passenger-waiting times efficiently given the linear programming model, with the characteristic of applying control intervals just every 5 minutes.

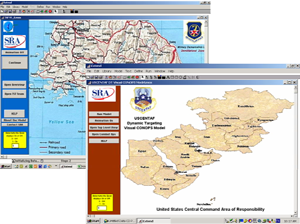

Aaron Newman, Steve Sokoly, Kevin Kennedy, Bobby Knight, Oliver Sadorra, Mike Baker, Ian Brown, Sharon Bemmerzouk, Kyle Ernest, Robin Leonard, William J. Sullivan IV, and Janet H. Dent; SRA International Inc.

10th ICCRTS Paper #263

13 April 2005

SRA provides analytic support to defense transformation through several modeling and analysis efforts. The project heavily dependent on knowledge of command and control capabilities and modernization is the Time Sensitive Targeting/Dynamic Targeting (TST/DT) model. Command and Control (C2) is recognized as the backbone for the TST/DT process. C2 functions are performed through an arrangement of personnel, equipment, communications, facilities, and procedures employed by a commander in controlling forces and operations in the accomplishment of the mission; therefore SRA has invested heavily in accurately capturing all portions of the C2 process relevant to TST/DT that can be modeled.

SRA uses ExtendSim, a commercial-off-the-shelf modeling environment, to develop a baseline model reflecting the latest Air Force Operational Tactics, Techniques, and Procedures (AFOTTP 2-3.2), including improvements from experiences in Operations Enduring Freedom (OEF) and Iraqi Freedom (OIF). SRA has used this baseline model to compare actual and exercise operations in various theaters and has used the model to analyze the performance of several initiatives in the Joint Expeditionary Force Experiment 2004 (JEFX 04). A logical out growth from this baseline TST/DT model is the development of a prototype Dynamic Targeting Debrief Tool (DT2).

Using GIS and Intelligent Transportation Tools for Biomass Supply Chain Modeling and Cost Assessment

Slobodan Gutesa, Agricultural Engineering

lowa State University

2013

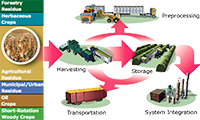

Stable, functional, and efficient bioethanol production systems on the national level must emphasize solutions of feedstock availability and transportation problems. Transportation logistics are a critical factor in the optimization of biomass supply chains. A single 25 million gallon per year cellulosic ethanol biorefinery will require delivery of 18,500 semi loads of bales to the plant. For a typical corn-stover biomass supply chain, baled corn stover must be transported in two phases, first from the field to a storage site and then from the storage site to the biorefinery. All activities between these two points are interconnected and together they form the biomass supply chain. The goal of supply-chain optimization is to minimize the total cost of these activities (transportation cost per unit, inventory cost per unit etc.) while satisfying the supply demands of a biorefinery.

Here the author uses a discrete modeling technique to make proper assessment of the supply-chain system performance. The supply-chain model was a representation of a realistic biomass transportation cycle between a single cornfield and biomass storage, including multiple simulations using different model factors.

SIMFAIL: Simulating Complex Fault Models for Onboard Systems

Integrated Group for Engineered Research

José Antonio Becerra Permuy, Luis Carral Couce, Diego Crespo Pereira, David del Río Vilas, Richard J. Duro Fernández, Alejandro García del Valle, Fernando López Peña, Nadia Rego Monteil, Rosa Ríos Prado

Electrorayma S.L.

Centro Tecnolóxico do Naval Galego

As vessels are often isolated at sea, the operability and reliability of their onboard equipment are of vital importance. Their definition, control and security are critical elements. At the same time, there are restrictions imposed by naval design and other factors, such as safety, and these must be recognised. Consequently the interrelationships that exist between various onboard systems are highly complex.

In this project simulation techniques were used for the complex task of predicting the interplay of effects related to faults between systems. By gathering and studying the data on elements of various ship systems, it was possible to obtain the statistical characterisation of their failure rates. This also made it possible to characterise the probabilities of failure in a system due to changes that another failure introduced.

The developed model allows the user to set different scenarios for performing preventive maintenance. It also helps assess how they can translate into probabilities of failure, as well as the cost of both equipment and between different systems. As a result, two models were developed. The first is a particular model for each element, which lets the user see the influence that delaying maintenance has in the case of more faults. Each element has some time between maintenance, completion time for each type of maintenance or cause of an error and failure rates. The second model establishes a system to represent the possibility of system failure due to a prior fault in another one.

Moreover, with this tool, one can determine the costs of different types of maintenance and how variations in maintenance time may increase or not these expenditures.

Report No Longer Available

Minotauro: Comprehensive Methods for Organizing Shipyard Work

Integrated Group for Engineered Research

David del Río Vilas, Richard J. Duro Fernández, Alba Martínez López, Diego Crespo Pereira, Fernando López Peña, Alejandro García del Valle

Centro Tecnolóxico do Naval Galego

Centro Tecnolóxico do Naval Galego

In a project for Astilleros Cardama (Cardama Shipyards), the Integrated Group for Engineered Research researched methods for sequencing the operations of both assembly and production in a workshop to reduce ship construction and repair time, minimise risk during assembly operations and lower operating costs from improper assembly and resource consumption. By generating systematic procedures for operational organisation, tracking and tracing different elements was facilitated and the implementation of quality systems promoted.

Using results from a detailed study of the operations taking place in the yard as well as precedence relations between tasks and the resource constraints involved, an ExtendSim model was built that included the variability and uncertainty caused by the arrival of new orders with different characteristics.

The model helped reduce production times and improve product quality. Moreover, the safety of workers increased, while the consumption of resources gets reduced.

Report No Longer Available

Mihails Savrasovs, Transport and Telecommunication Institute, Riga, Latvia

Presented at the 2011 European Conference on Modelling and Simulation, Kraków, Poland

This paper uses a discrete rate approach to modeling in ExtendSim simulation software for urban transport corridor simulation. Such mesoscopic traffic flow models should be understood as models where traffic flow is described in a high level of detail, but at the same time flow behavior is presented at a low level of description. Since the discrete rate approach is typically not used in the transport area, this paper presents the main techniques of model implementation using a discrete rate approach and the application of this approach for urban transport corridor simulation. The author concludes that development time of the mesoscopic model is approximately 5 times less than adevelopment of the same microscopic model.

US Department of Energy, Oak Ridge National Laboratory, Idaho National Laboratory, and the National Renewable Energy Laboratory

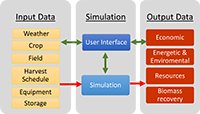

The U.S. Department of Energy, Oak Ridge National Laboratory, Idaho National Laboratory, National Renewable Energy Laboratory, and other research organizations collaborated on the Integrated Biomass Supply Analysis & Logistics (IBSAL) model developed in ExtendSim. This biomass supply chain model takes into consideration the logistical features of a supply such as the number of farms involved, average yield, the start and progress of harvest schedule, the moisture content of the crop, daily weather data, equipment specifications, and so on. Using this information, the model calculates drying and wetting of the biomass and workability of the soil. It is also being used to calculate costs per ton of biomass, energy input, and emissions (CO2) from equipment.

Development and Implementation of Integrated Biomass Supply Analysis and Logistics Model (IBSAL)

Shahab Sokhansanja, Amit Kumarc, and Anthony F. Turhollowa -- Environmental Sciences Division, Oak Ridge National Laboratory; Department of Chemical and Biological Engineering, University of British Columbia; Department of Mechanical Engineering, University of Alberta

Science Direct,

October 2006

This paper describes the framework development of a dynamic integrated biomass supply analysis and logistics model (IBSAL) to simulate the collection, storage, and transport operations for supplying agricultural biomass to a biorefinery. The model built in ExtendSim consists of time dependent events representing the working rate of equipment and queues representing the capacity of storage structures. Weather conditions including rain and snow influence the moisture content and the dry matter loss of biomass through the supply chain are included in the model.

Greg Hansen

Wine Business Monthly

October 2000

This article describes the use of simulation to create a cognitive model of the actions of certain winery workers.

Simulation of the Grape Reception at a Winery

Andrés Auger, Juan-Carlos Ferrer, Sergio Maturana, and Jorge Vera

>School of Engineering at the Universidad Católica de Chile

November 6, 2003

Improvement of grape supply management - in terms of amounts and availability schedules - is of paramount importance. Researchers developed a simulation model of the reception of the grape to help redesign the operation of the supply chain of the winery in order to minimize the delays in processing the grapes, by making good use of the existing equipment. By experimenting with the model, it was determined that there were certain changes that could reduce these delays. During the vintage, the rapid pace of the events, and the uncertainties of many aspects of the operation, makes it very difficult for management to make good decisions. The development of a simulation model was important for understanding the effects that certain changes could produce during the vintage in order to be better prepared and make better decisions.

Smew, W.; Young, P. & Geraghty, J.

Enterprise Process Research Centre, School of Mechanical and Manufacturing Engineering, Dublin City University, Dublin, Ireland

2013

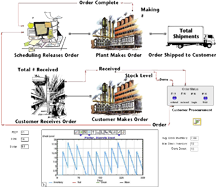

This paper presents a simulation study on production and inventory control at the supply chain (SC) level and examines through a series of experiments the potential impact of the Hybrid Kanban-CONWIP production control strategy on the trade-off between the conflicting objectives of maximising customer service level and minimising Work-In-Process (WIP). Simulation based optimisation is computationally expensive approach to determining an optimal configuration of operational parameters for any stochastic system.

1Point2

Sassenage, France

This report presents an integrated simulation-based approach to study the on-site production of concrete frameworks by considering the multiple effects of weather on work task productivity and concrete curing process. The ExtendSim model created reports simulated construction time, cost, and CO2 emissions for a specific construction setup to facilitate planning and decisions related to resource allocation strategies, construction schedules, different concrete types (including climate-improved concrete), and curing measures for different types of expected weather conditions.

Argentine Association of Business Logistics (ARLOG)

Universidad Argentina de la Empresa (UADE)

2008

Argentine Association of Business Logistics (ARLOG) awarded to the Universidad Argentina de la Empresa (UADE) the ARLOG 2008 award for a project they did in conjunction with GL&A Consultants. The team developed a discrete stochastic simulator for freight trains carrying cereals, oils, and other products to the ports of Bahía Blanca and Rosario from producing areas in Argentina to improve the logistical capacity of the company. The operation of the entire system is very complex it models a multitude of locomotives in constant motion to move several thousand wagons for the rail network, subject to mechanical, climatic, and human contingencies.

The prestigious ARLOG award is granted biennially to projects that deepen and promote the development, innovation, and professionalization of logistics management.

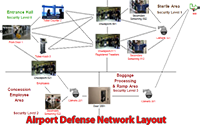

William Wiess, Mitre Corporation

Proceedings of the 2008 Winter Simulation Conference

The Department of Homeland Security (DHS) shifted the focus of airport security to incorporate the need to continuously and rapidly adapt security to shifting threats. MITRE corporation developed a Dynamic Security Airport Simulation in which attacker and defense behavior in the airport environment are modeled. The simulation accepts threat vectors (path-weapon combinations) from other software or the user and models the performance of the airport defense against those threat vectors. The simulation includes two intelligent agents: the attacker and the defense. These agents model the behavior of those two entities; their logic includes both decision making and learning.

Prepared for the United States Air Force by Mahyar A. Amouzegar & Lionel A. Galway of the RAND Corporation

Released for unlimited distribution 2003

Engine Maintenance Systems Evaluation (EnMasse) is a simulation model built in ExtendSim and used in the analysis of alternative Jet Engine Intermediate Maintenance (JEIM) policies. The result of the policy analysis conducted using EnMasse is reported in a companion document, Supporting Expeditionary Aerospace Forces: Alternatives for Jet Engine Intermediate Maintenance, MR-1431-AF, 2002, ISBN 978-0833031037. The goal of this analysis was to evaluate several alternatives for accomplishing JEIM support. Closely allied to maintenance policy are the maintenance structures within which these policies operate both in peace and war.

IIE Solutions

DynMcDermott Petroleum Operations Company (DM), managing and operating contractor for the Department of Energy Strategic Petroleum Reserve (SPR), initiated reengineering of the SPR supply chain to reduce expenses, decrease need-fulfillment time, and improve the storage and dissemination of information.

Susan Hutchins, Gordon Schacher, John Looney, Jack Jensen, John Osmundson, and Shelley Gallup from the Naval Postgraduate School; James Dailey and Steven Saylor from The Boeing Company

10th International Command and Control Research & Technology Symposium

May 2005

Boeing and the Naval Postgraduate School (NPS) developed an ExtendSim model of an organizational concept called Standing Joint Forces HQ (SJFHQ) being developed at the US Joint Forces Command (JFCOM). The modeling objective was to measure personnel utilization and organizational process efficiency. Here is the NPS final report and an abbreviated presentation given at a public command and control conference. The final report contains a lot of information about the actual ExtendSim model developed.

Lisa M. Fitzgerald & Tiffany J. Harper, Nova Technology Solutions

Proceedings of the 2008 Winter Simulation Confence

The United States Air Force, in accordance with the Department of Defense's mission to modernize its processes, systems, and information flows, began an effort to replace legacy systems with two Enterprise Resource Planning (ERP) systems. Nova Technology Solutions (NovaTech), an Information Technology (IT) and Analytics firm, recognized the Air Force's need for a repeatable, reliable, tool to aid decision making during the planning, installation, and sustainment of these ERP systems, thus proposing the use of modeling and simulation.

ExtendSim was used to create a simple simulation model to analyze the impact of ERP increased workload on network performance by simulating the flow of data packets, specifically at the Air Force Service Delivery Points (SDPs). Results showed a 15% increase in current workload (or current network traffic) will cause a 250% increase in end-user response time.

Implementation of Simulation for Network Service Delivery Point Capacity Analysis

Tiffany J. Harper

Wright State University

Further enhancements were made to the NovaTech model by Tiffany Jill Harper for a thesis submitted for the degree of Master of Science in Engineering at Wright State University. Her thesis showed a 98%, 209%, and 352% increase in response time when the current workload is increased by 10%, 20%, and 30%, respectively.

Ilmars Dukulis, Gints Birzietis, Daina Kanaska of the Latvia University of Agriculture

7th International Scientific Conference on Engineering for Rural Development

Biofuels are transport fuels made from organic material. The most common biofuels today are biodiesel (made from vegetable oils) and bioethanol (made from sugar and starch crops). Research is under way to commercialize “second-generation” production techniques that can make biofuels from woody material, grasses, and some additional types of waste. Biofuels have a unique role to play in European energy policy. They are today the only direct substitute for oil in transport that is available on a significant scale.

This paper that was originally presented at the 7th International Scientific Conference on Engineering for Rural Development in May of 2008 in Jelgava, Latvia. It provides a short overview of the strategies and action plans in production and use of biofuels in Europe and Latvia. Then, existing solutions in the improvement of biofuel logistic systems are analyzed as well as ExtendSim as a tool for the modeling of biofuel supply chains.

Videos

OSILI - Demonstrating the contractual performance of the FDM performance of the LGV SEA

The OSILI model developed in ExtendSim, studies the design and operational issues of the TGV between Tours and Bordeaux, to determine whether the high-speed trains meet reliability, availability, and regularity criteria.

OSILI represents the whole of the LGV SEA line. It allows the simulation of incidents on the line to better understand an incident's impact and calculate the ensuing delays. Simulation provides precise results, making it possible to replay incidents and better evaluate arbitration rules.

Building a Discrete Event Model of an Airport Security Checkpoint

Learn to build a discrete event model in just 4 minutes! Use ExtendSim to simulate an airport security checkpoint. See how any change made to the security process can effect passengers going through the checkpoint.

Download Paper

Download Paper

Download ExtendSim Model

Download ExtendSim Model

Bioenergy Knowledge Discovery Framework

Bioenergy Knowledge Discovery Framework